From patient comfort to technical precision: how the Robert Laboratory optimizes dental prosthetics

In a sector where comfort, aesthetics, and turnaround times are crucial, the Robert Dental Laboratory has taken a decisive step. The first French laboratory to adopt Stratasys' TrueDent™ monolithic dental prosthesis 3D printing technology, the laboratory has redefined its production model — to the direct benefit of patients and practitioners. This transformation serves as a compelling dental 3D printing case study, showcasing the impact of digital dentures with TrueDent on dental production and dental practices.

“We can now do in an afternoon what used to take us three days,” explains Christophe Robert, founder of the laboratory. This increased speed not only allows for faster delivery of prostheses but also reduces patient treatment times and the number of necessary appointments.

This advance builds on Mr. Robert's success with Stratasys J5 DentaJet dental workflow, which he used to produce dental models, surgical guides, and gingival masks. Having closely followed the evolution of TrueDent digital dental prosthesis technology, he immediately implemented the system as soon as it became available in early 2025.

The cornerstone of this productivity leap is the 50% reduction in handling time offered by the solution, a key factor that has transformed their production approach:

Today, the Robert Laboratory produces complete removable prostheses, partial resin prostheses, and frameworks with metal chassis, all in a single production unit.

This versatility, combined with a 50% reduction in handling time, allows for a 75% increase in capacity and thus considerable growth in its business.

More precise fit, more comfortable prostheses

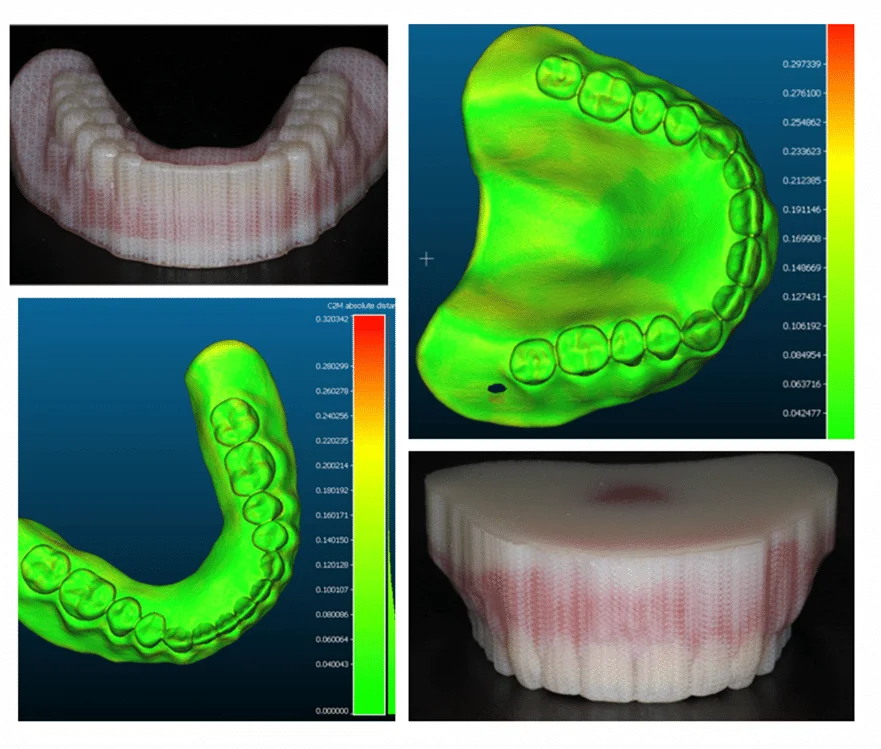

PolyJet 3D printing achieves 18.75 µm precision, ensuring an optimal fit from the first fitting. The process of manufacturing prostheses in a single 3D printing operation eliminates assembly steps that introduce variability in the traditional process, enhancing the precision of the prostheses.

For the patient, this translates into a more comfortable fit with much fewer fittings.

The TrueDent™ system's digital workflow, integrated with intraoral scanners and CAD/CAM software, enables a smooth production chain, directly impacting the work of dental practices.

The reliability of the prostheses and delivery within a few days contribute to reducing follow-up appointments and waiting times for their patients.

Thanks to the multi-material capability of PolyJet technology, each prosthesis is made with variations in shade and translucency that faithfully mimic natural teeth and allow for customization of prostheses for each patient.

Practitioners gain in efficiency and peace of mind, being able to offer more comfort and aesthetics, thus improving the overall patient experience while simplifying the clinical workflows of dental practices.

The financial impact of implementing TrueDent™ was significant enough for the Robert Laboratory to anticipate a full return on investment in just 12 months.

The TrueDent workflow of the J5 DentaJet generates savings in many areas:

By adopting TrueDent™ technology, the Robert Laboratory has established itself as a leader in dental innovation. The laboratory now offers dental professionals and patients better quality prostheses, shorter execution times, and more consistent results, all at controlled costs that preserve their profitability.

As the dental sector continues its digital transformation, advanced manufacturing technologies, such as Stratasys' PolyJet 3D printing, set new standards for dental laboratories. For the Robert Laboratory, adopting this technology has not only improved its production indicators but also positioned it at the forefront of digital dentistry.

Far from being a mere technological feat, the adoption of TrueDent™ has resulted in a tangible transformation of the care experience: more human, more precise, faster. Today, the Robert Laboratory embodies the convergence of industrial performance and quality of care, in a modern vision of dentistry.