FDM材料

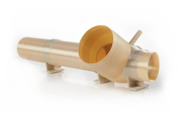

FDM技术使用同样坚固稳定的热塑性塑料,此类塑料用于注塑成型、数控机床加工和其他传统制造工艺。FDM热塑性塑料能够满足对于高度要求配合紧密性、韧度和环境耐受性或特殊性质 (如静电消散、半透明度、生物相容性、VO 可燃性和 FST 评级方面) 的应用。

PC

强韧(拉伸)

PC-ISO

生物相容性

PLA

快速草图打印、高分辨率零件

PPSF/PPSU

高抗性(热、化学品)

ULTEM™ 9085 resin

机械性能出众。经过FST认证,提供ULTEM™ 9085 resin 航空航天树脂材料

FDM 尼龙6

强(冲击),韧性(高抗疲劳性)

ULTEM™ 1010 resin

食品安全与生物相容性认证。高的耐温性

FDM 尼龙12

强(高抗疲劳性)

FDM 尼龙12CF

良好的抗弯强度。良好的硬度-重量比

ST 130

针对牺牲工具而设计

Antero 840CN03

聚醚酮酮 (PEKK) 材料,属于聚芳醚酮(PEAK)系列。它是一种半结晶态、高性能热塑性树脂,以其强度、耐高温性和优异的耐化学性而著称。

Diran 410MF07

尼龙系列工程级热塑塑料,含 7% 的矿物物质。它具有出色的韧性和冲击强度,同时光滑的表面可提供低滑动阻力。

PolyJet材料

PolyJet 3D打印机使用光敏树脂材料,该材料能够模拟从类橡胶到透明材料在内的多种材料特性 -- 甚至还可模拟高韧性和高耐热性。数字材料通过混合两种或多种基本树脂得到成百上千的材料混合,扩大了材料可能性。实现全面色彩功能、肖氏硬度 A 值和其他特性,达到大的产品逼真度。

数位材料

- 灵活性高,肖氏硬度A值范围从27到95

- 刚性材料范围从模拟标准塑料到硬且耐高温的数字 ABS Plus

- 刚性或柔性材料鲜艳多彩,Stratasys J750 多达 360,000 种颜色选择

- PolyJet 多重喷射 3D 打印机可用

耐高温材料

- 非一般的尺寸稳定性,适用于热功能测试

- 结合 PolyJet 类橡胶材料制作不同肖氏硬度 A 值、灰度和耐高温的包覆成型部件

- 适合用于形状、外观和热功能测试、需要表面质量优异的高清模型、可耐受强光的展览模型、水龙头、管道和家具电器,热气和热水测试

透明材料

- 使用 VeroClear 和 RGD720 打印彩色透明部件和原型

- 结合多彩材料实现非凡的透明度

- 适合用于透明部件的形状和外观测试,如玻璃、消费品、护目镜、灯罩和灯箱、液体流动情况可视化、医疗应用、艺术和展览建模

刚性不透明材料

- 绚丽色彩选择带来前所未有的设计自由

- 结合类橡胶材料,用于包覆成型、质感柔软的手柄等

- 适合用于形状和外观测试、移动部件和组装件、销售、营销和展览模型、电子部件组装和硅胶成型

类聚丙烯材料

- 模拟聚丙烯外观和功能

- 适合用于容器和包装、灵活的卡扣配合应用和活动铰链、玩具、电池盒、实验室设备、扬声器和汽车零部件原型制作

类橡胶材料

- 可提供不同程度的弹性体特征

- 结合刚性材料来模拟多种肖氏硬度 A 值,范围从肖氏硬度 A 27 至肖氏硬度 A 95

- 适合用于橡胶挡板、包覆成型、触感柔软的镀膜与防滑表层、按钮、握柄、拉手、把手、垫圈、密封件、软管、鞋类以及展览和通讯模型

生物相容性

- 尺寸稳定性高、无色透明

- 拥有五项医疗审批,包括细胞毒性、基因毒性、迟发型超敏反应、刺激性和 USP VI 级塑料

- 适合用于皮肤接触超过 30 天以及短期粘膜接触长达到 24 小时的应用