Manufacture production parts on-demand, without the high cost and long lead times of traditional machining and molding technologies.

3D printing requires no production tooling so you can bypass traditional time and cost constraints to quickly manufacture products. Print parts on-demand and save on inventory and storage while avoiding the lead times associated with designing and creating production tooling. Whether you’re making aircraft parts or fashion accessories, 3D printing provides a scalable process for making custom and mid-volume production economically viable, and higher volume production more efficient than traditional processes.

The traditional way to make things – machining and molding – has inherent constraints. As this solution guide shows, 3D printing with SAF powder bed technology offers an effective alternative.

Virtually any industry that manufactures products can benefit from the efficiencies of 3D printing.

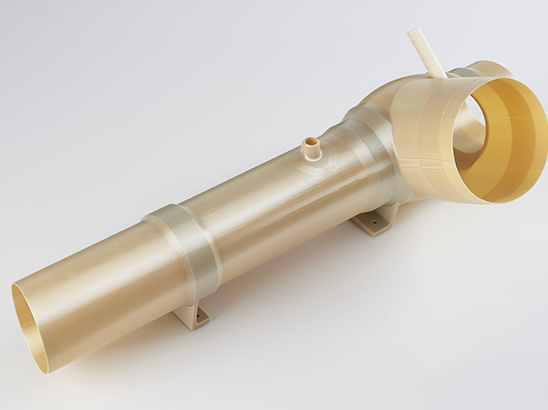

Stratasys 3D printing solutions offer the materials and processes to satisfy regulatory requirements of the air and space industry.

Rapid prototype for mission-critical parts, reduce logistics and supply chain risks, and establish on-demand readiness.

View more3D printing is the perfect solution for highly customized parts and viable low to mid-volume production.

Develop and deliver your products faster by leveraging 3D printing’s ability to make the production cycle more agile.

Rapid prototype for mission-critical parts, reduce logistics and supply chain risks, and establish on-demand readiness.

View moreTim Ganley, Managing Director, Go Orthotics

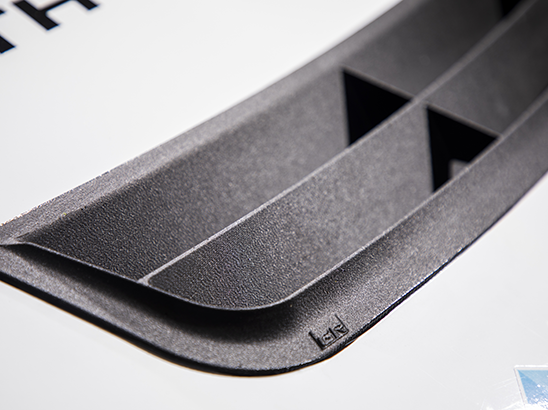

Customer Success StoryPost-processing may include steps such as sanding, painting, or coating to achieve the desired finish and mechanical properties.

3D printing can be more environmentally friendly than traditional manufacturing due to reduced material waste and the ability to produce parts locally, reducing transportation emissions.

3D printed production parts are functional, customer-ready components made directly from digital designs. They enable faster turnaround, lower costs, and easier design updates for low- to mid-volume production.

As an additive process, there’s no need to use molds, jigs, or fixtures to manufacture 3D printed production parts.

Stratasys offers materials like ABS, ASA, PC, Nylon, ULTEM™, carbon-fiber composites, elastomers like TPU, and more. Filter for strength, heat resistance, flexibility, and/or compliance, depending on your application.

Many parts can be printed within 1–2 days, especially for short runs. Larger batches or certification-heavy applications may take longer but are still significantly faster than traditional production timelines.

Industries like aerospace, automotive, consumer goods, industrial equipment, and medical all benefit from using additive manufacturing as part of their production parts toolkit.

Start by sharing your part requirements. Our team will help select the right printer, material, and process to meet your production needs – whether you're scaling a pilot or replacing traditional manufacturing altogether.

When a production change forced the redesign of a truck camera mount, 3D printing made it possible to still meet the schedule.

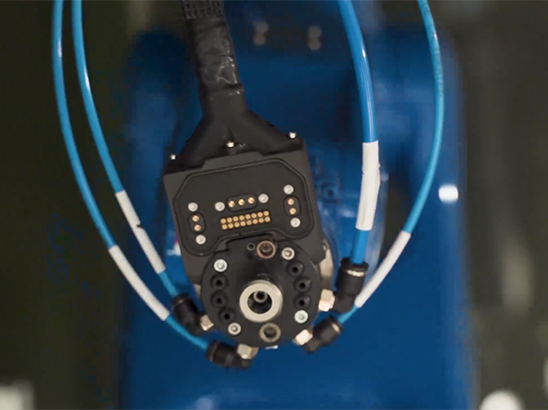

The lack of an off-the-shelf part solution for its production robots led Rivelin Robotics to 3D print its own parts.